4 – 20ma Lightweight Ultrasonic Level Sensor KUS550. Due to their ruggedness and low cost, ultrasonic sensors are widely used in various consumer and industrial areas as an advanced and well-known technology.

When adding a measuring distance or detection function to a product, an ultrasonic sensor is the ideal option. Furthermore, it has a broader applicability and improved dependability in hardware upgrades and software adaptations.

An ultrasonic sensor is a type of electronic equipment that emits ultrasonic sound waves and converts the reflected sound into an electrical signal to determine the distance of a target item.

Ultrasonic waves travel quicker than audible sound (i.e. the sound that humans can hear).

The transmitter, which generates sound using piezoelectric crystals and the receiver, which encounters the sound after it has traveled to and from the target, are the two primary components of ultrasonic sensors.

4 – 20ma Lightweight Ultrasonic Level Sensor KUS550

Features

- Small size

- Working frequency bandwidth

- high sensitivity

- Wide application scenarios

Model: KUS550

Measuring range:

KUS550A: 0.25m~3m (5m can be customized)

KUS550B: 0.15m-0.6m (1m can be customized)

Supply voltage: 3.3 … 30 VDC, ripple 10 %SS

Power consumption: less than 0.3mA in sleep state, less than 20mA in wave-emitting state, and less than 5mA in detection state

output signal:

1. 0-3V, 0-5V/4-20mA/NPN/PNP/TTL;

2. RS485 Modbus.

Measurement accuracy: ≤1% (0.5% in laboratory)

Temperature Compensation: Yes

Working environment temperature: -25…70℃ (248…343K)

Storage temperature: -40…85°C (233…358K)

Electrical connection: 5-core/6-core cable

Protection class: IP68

Shell material: PVDF

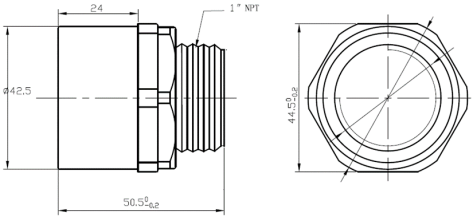

Installation Diagram

Structure size

Ultrasonic sensors are mostly utilized as proximity sensors. They can be found in self-parking technology and anti-collision safety systems in automobiles.

In addition to robotic obstacle detection systems, ultrasonic sensors are used in manufacturing technology.

Ultrasonic sensors are less susceptible to interference from smoke, gas, and other airborne particles than infrared (IR) sensors in proximity detection applications (though the physical components are still affected by variables such as heat).

Ultrasonic sensors are also utilized as level sensors in closed containers to detect, monitor, and manage liquid levels such as vats in chemical factories.

Most notably, ultrasonic technology has allowed the medical profession to create images of interior organs, spot malignancies, and monitor the health of newborns in the womb.

Related Guides